Department of Automation and Robotics Engineering is recently established by the Institute from A.Y. 2021-22 with a UG program of intake capacity of 60. This program is approved by AICTE, New Delhi and Affiliated to the Savitribai Phule Pune University. Automation is an indispensable part of the manufacturing industry, the majority of companies today are looking for lean manufacturing solutions and Robotics provide many benefits that companies require to stay competitive. Robotics is a key technology player in Industrial Revolution 4.0 and its impact assessment demands a futuristic outlook to live through its complete evolution. Adoption of robots have started making repetitive and assembly line kind of jobs redundant in sectors like automobiles, pharma, IT and ITES, financials, electronics…the labour force is changing and it will continue in India for the next several years.

A futuristic and forward looking vision is specifically important for India as robotics is still novel and its impact and consequences are yet to unfold.

Automation and Robotics Engineering is an emerging multi-disciplinary course that requires profound application based knowledge in hardware as well as software development, which comprise design, construction, operation, and application of robots. The design of a robotic system puts together basics of mechanical engineering, manufacturing engineering, electrical/electronics Engineering, and Computer engineering. A specialized undergraduate degree in Automation and Robotics Engineering will enable students to serve the Industry requirement for implementation of new and smart autonomous technologies covering methods of synthesis, analysis and optimization of newer robots and mechanisms. Automation and Robotics Engineering involves design development and up-gradation in terms of automating products, systems and processes in every aspect of life. The graduate of this course will hit upon abundant opportunities to work as Robot design engineer, robot programmers, robotics system engineer etc. in the field of industrial automation, manufacturing, automobile, agriculture, mining, aerospace, defence, social and health care.

The department has a well-qualified, devoted and experienced faculty with average experience more than 10 Years. Two faculty members are with Ph.D. qualification and others with master’s degree in relevant field. Department is well equipped with state-of-the-art equipment and Laboratories like Robotics Lab, e-yantra VLSI embedded lab (IIT Powai support),Automation and control Lab, CAD/CAM Lab, Robotic Simulation Lab etc. with excellent computational facilities including professional software packages, such as MATLAB, SolidWorks, Do-NC, Coppeliasim and Robotstudio robot simulator etc. Workshop is an excellent Manufacturing centre with state of the art machines including CNC, VMC, CMM and other industry grade machines.

Create able Automation and Robotics engineers through excellence in academics and industry – institute – interaction.

| Sr. No. | Class - Room Description | Area, Sq. m. | Rooms Equipped with |

|---|---|---|---|

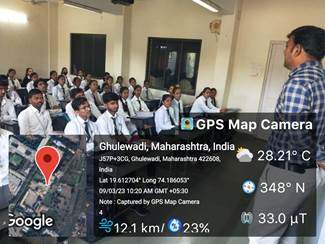

| 1 | F.E. Class room | 78.75 | Green Board, Seating arrangements, Ceiling Fans, Tube lights, CCTV Camera, LCD Projector. |

| 2 | S.E. Class room | 78.75 | Green Board, Seating arrangements, Ceiling Fans, Tube lights, CCTV Camera, LCD Projector. |

| 3 | T.E. Class room | 78.75 | Green Board, Seating arrangements, Ceiling Fans, Tube lights, CCTV Camera, LCD Projector. |

| 4 | B.E. Class room | 78.75 | Green Board, Seating arrangements, Ceiling Fans, Tube lights, CCTV Camera, LCD Projector, Smart Board. |

| 5 | Seminar Room | 175 | PC, Internet, Green Board, Table, PA System, Ceiling Fans, Artificial Light (Tube lights). CCTV Camera. |

| Sr. No. | Name of the laboratory | Area, Sq. m. | Major Equipment |

|---|---|---|---|

| 1 | Advanced Robotics Lab | 78.50 |

1. ROS IoT based SCARA robot system

2. Robot gripper setup 3. 6DOF IoT based DOBOTS 4. ROS IoT based Cartesian robot system |

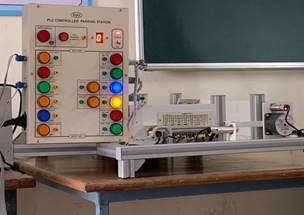

| 2 | PLC Lab | 78.50 |

Siemens S7-1200 PLC

Interfacing Kits: 1. Servo motor 2. Stepper motor 3. Car parking 4. Wireless communication module 5. Temperature control |

| 3 | Automation & Control Lab | 70 | Electro-Hydraulic Trainer, Pneumatic trainer, PLC trainer, Microprocessor 8086 trainers kit, Microcontroller kit compressor, 4kg Capacity |

| 4 | Advanced machine tool Lab | 80 |

1. Coordinate Measuring Machine (CMM), Electronica Make, Saphire 464

2. Computer Numerical Control Machine (CNC), LMW Make, Smarturn 3. Vertical Milling Center (VMC), Jyoti Make, PX30 |

| 5 | Metrology & Quality control Lab | 70 | Tool Maker's Microscope, Surface Finish Tester, Profile Projector, Sine Bar, Electronic Comparator with Probe, Vernier Caliper, Dial Caliper, `V' anvil Micrometer, Gear Tooth Caliper, Slip Gauges Set (83 Pieces), Ring Gauge, Wire Gauge, Angle Gauge, Universal Surface Gauge |

| 6 | Robotics Lab | 70 |

1. 6-Axis Programmable ABB IRB1400 Robotic Arm System with Pick and place gripper.

2. Robotic MIG welding set up. 3. e-yantra kits under VLSI Lab setup initiative supported by IIT Powai. |

| 7 | CAD/CAM Lab | 175 |

1. Master CAM V-2023

2. Unigraphics NX 7.5 3. Del CAM 4. Cadem 5. Autocad 2023 6. Ansys |

| 8 | Robot Programming Lab | 70 |

1. RoboDK

2. Robo Analyzer 3. Witness Simulation Software 4. MATLAB 2023-2 |

| Photo | Faculty name and description |

|---|---|

|

Name

: Dr.V.B.Shinde

Designation : Asst.Prof. & HOD Qualification : M .Tech.(Mech), Ph.D Exp Teaching : 20 yrs Exp Industrial : 01 yrs Area of Specialization: Robotics and Automation Biodata: Read More |

|

|

Name

: Dr. B.R.Borkar

Designation : Professor Qualification : M.Tech.(Prod), PhD (Mech) Exp Teaching : 27 yrs Exp Industrial : 03 yrs Area of Specialization: CAD/CAM, Automation Biodata: Read More |

|

Name

: Dr.R.S.Tajane

Designation : Asso.Prof.,WS Qualification : M.E.(Mech) PhD (Prod.) Exp Teaching : 34 yrs Exp Industrial : 01 yrs Area of Specialization: Manufacturing Engineering Biodata: Read More |

|

|

Name: Dr. V. S. Gadakh |

|

Name

: Prof.N.S.Khemnar

Designation : Asst.Prof. Qualification : M.Tech.(Prod) Exp Teaching :19 yrs Exp Industrial : 01 yrs Area of Specialization: Metrology and Quality Control Biodata: Read More |

|

Name

: Prof.H.P.Pathade

Designation : Asst.Prof. Qualification :M.E.(Mech), P.hD Appear Exp Teaching :14 yrs Exp Industrial : Nil Area of Specialization: Manufacturing Technology Biodata: Read More |

|

Name

: Prof.S.N. Gadhave

Designation : Asst.Prof. Qualification : M.E. Prod(CAD/CAM) Exp Teaching :15 yrs Exp Industrial : 2 yrs Area of Specialization: CAD/ Cam, Management Biodata: Read More |

|

Name

: Prof.P.B.Wakchaure

Designation : Asst.Prof. Qualification :M.E.Prod(CAD/CAM) Exp Teaching : 10 yrs Exp Industrial : 07 yrs Area of Specialization: Process Planning, Metrology & Quality Control Biodata: Read More |

|

Name

: Prof.M.J.Thokale

Designation : Asst.Prof. Qualification :M.Tech.(Mfg Engg & Auto) Exp Teaching :14 yrs Exp Industrial : Nil Area of Specialization: CAD/ CAM, Manufacturing Biodata: Read More |

|

Name

:

Dr.N.J. Varpe

Designation : Asst.Prof. Qualification :M.E.(CAD/CAM), P.hD Exp Teaching : 10 yrs Exp Industrial : 02 yrs Area of Specialization: Industrial Automation, Manufacturing Biodata: Read More |

|

Name

:

Prof . S. K. Bangar

Designation : Asst.Prof. Qualification :M.E.(Adv. Manuf. System) Exp Teaching : 10 yrs Exp Industrial : 07 yrs Area of Specialization: Advanced Manufacturing Systems Biodata: Read More |

|

Name

:Prof. V.R. Wakchaure

Designation : Assistant Professor Qualification : Exp Teaching : 4 yrs Exp Industrial : 0 yrs Area of Specialization: Biodata: Read More |

| Photo | Description |

|---|---|

|

Name

:

. P.V. Matey Designation : Adjunct Prof. Qualification :B.E.Mech, MMS Exp Teaching : 5 yrs Exp Industrial : 24 yrs |

|

Name

:

. P.B.Kushare Designation : Adjunct Prof. Qualification :B.E.Prod, MTech Energy Mgt. Exp Teaching : 3 yrs Exp Industrial : 23 yrs |

| Photo | Description |

|---|---|

|

Name

: Mr.D.B.Karpe

Designation : Tech Asst. Qualification : D.M.E. Exp Working : 10 yrs Exp Industrial : 01 yrs |

|

Name

:Mr.L.G.Gunjal Designation : Lab Asst. Qualification : I.T.I. Exp Working : 20 yrs Exp Industrial : Nil |

|

Name

: Mr.V.V.Roham

Designation : Tech.Asst. Qualification :D.M.E. Exp Working :06 yrs Exp Industrial : Nil |

|

Name

: Mr.J.P.Kakad Designation : Tech.Asst. Qualification : D.M.E. Exp Working : 06 yrs Exp Industrial : Nil |

|

Name: Mr. S. B. Pawar

Designation : Peon Qualification : S.S.C. Exp Working: 20 Exp Industrial: Nil |

|

Name

: Mr. Argade Mahendra Shivaji Designation : Peon Qualification : S.S.C. Experience : 5 yr |

| Sr. No | Faculty Name | Paper Title | Journal Name | ISSN/DOI | Link |

|---|---|---|---|---|---|

| Academic Year 2023-2024 | |||||

| 1 | Dr. N. J. Varpe | Investigation into Burnishing Process to Examine Effect on Surface Integrity, Wear and Corrosion Resistance of Carbon Alloy (EN31) Steel. | Journal of Materials Engineering and Performance | DOI: 10.1007/s11665-023-08524-x | https://link.springer.com/article/10.1007/s11665-023-08524-x |

| Academic Year 2022-2023 | |||||

| 1 | Dr. V. S. Gadakh | Relative Tool Wear and Metal Removal Studies in Electric Discharge Machining of AISI D2 Die Steel Using Cu-Cr-Zr, Cu-Cd, and Cu-Be Electrode Materials | Journal of Materials Engineering and Performance | DOI: 10.1007/s11665-023-08264-y | https://link.springer.com/article/10.1007/s11665-023-08264-y |

| 2 | Prof. N. J. Varpe | Multi Objective Optimization Of Burnishing To Eliminate Heat Treatment In Reamer Shank Manufacturing By Using Taguchi Coupled Principal Component Analysis (PCA) | Advances in Materials and Processing Technologies | DOI: 10.1080/2374068X.2022.2118931 | https://www.tandfonline.com/doi/abs/10.1080/2374068X.2022.2118931 |

| Academic Year 2021-2022 | |||||

| 1. | Prof. N. J. Varpe | Optimization of Burnishing process by Taguchi method for surface enhancement of EN31 steel | Surface Topography: Metrology and Properties | DOI: 10.1088/2051-672X/ac4f37 | https://iopscience.iop.org/article/10.1088/2051-672X/ac4f37/pdf |

| Sr. No | Faculty Name | Achievement Details |

|---|---|---|

| Academic Year 2023-2024 | ||

| 1. | Dr. N. J. Varpe |

Successfully completed / attended following trainings / workshop / FDP/ seminar / webinar:

1. Workshop on Internal Auditors Training-EOMS 2. FDP on Prototype Development 3. 7 Days National Level FDP On PYTHON 4. Webinar on Entrepreneur as Career 5. Webinar on Introduction to additive manufacturing 6. Workshop on NEP 2020 |

| 2. | Dr. N. J. Varpe | Acted as Reviewer for the 3 rd International E-Conference on Mechanical and Material Science Engineering: Innovation and Research (ICMMSE:IR 2023) Organized by Department of Mechanical Engineering, Sandip Institute of Technology & Research Centre, Nashik (MS) (An Autonomous Institute) on 12 & 13 December 2023. |

| 3. | Dr. V. S. Gadakh |

Successfully completed / attended following trainings / workshop / FDP/ seminar / webinar:

1. Workshop on Internal Auditors Training-EOMS 2. STTP on Recent Developments in Materials and Manufacturing Processes 3. Webinar on AI AND ROBOTICS 4. Webinar on Unlocking Design excellence with 3Dexperience platform and simulation using Solidworks. 5. Workshop on NEP 2020 6. Workshop on Novel Materials: Processing and Characterization |

| 4. | Dr. V. B. Shinde |

Successfully completed / attended following trainings / workshop / FDP/ seminar / webinar:

1. Workshop on Internal Auditors Training-EOMS 2. Workshop on NEP 2020 |

| 5. | Dr. B. R. Borkar |

Successfully completed / attended following trainings / workshop / FDP/ seminar / webinar:

1. Workshop on Training of Trainers (ToT) 2. Workshop on Recent advances in Robotics |

| Academic Year 2022-2023 | ||

| 1. | Prof. N. J. Varpe |

Successfully completed following training conducted by NITTT in association with All India Council for Technical Education (AICTE)

Module 3: Communication Skills, Modes and Knowledge Dissemination Module 5: Technology Enabled Learning and Life-Long Self Learning Module 6: Student Assessment and Evaluation |

| 2. | Prof. S. K. Bangar |

Successfully completed following training conducted by NITTT in association with All India Council for Technical Education (AICTE)

Module 5: Technology Enabled Learning and Life-Long Self Learning Module 6: Student Assessment and Evaluation Module 7: Creative Problem Solving, Innovation and Meaningful Research and Development Module 8: Institutional Management and Administrative Procedures |

| Academic Year 2021-2022 | ||

| 1. |

Prof. N. J. Varpe

Prof. S. K. Bangar |

Successfully completed following training conducted by NITTT in association with All India Council for Technical Education (AICTE)

Module 1: Orientation towards Technical Education and Curriculum Aspects. Module 2: Professional Ethics and Sustainability. |

| Sr. No. | Date | Name of Activity | Class | Outcomes |

|---|---|---|---|---|

| Academic Year: 2024-25 | ||||

| 1. | 05/09/2024 | Teachers Day Celebration | SE,TE | Fostered a sense of appreciation & respect for educators, strengthened student-teachers bond. |

| 2. | 15/09/2024 | Poster making competition | Students of all dept. | Students got the opportunities to showcase their technical skill through various posters. |

| 3. | 14/08/2024 & 28/08/2024 | Group Discussion, Debate Competition, Extempore | SE,TE | These activities provided A&R students with engaging experiential learning opportunity that promotes teamwork, creativity, problem-solving, leadership development, time management and reflection, contributing to their holistic education and professional development. |

| Academic Year: 2023-24 | ||||

| 1. | 22/09/2023 | Robo Show | SE,TE | Students got the opportunities to showcase their technical skill through various robots. |

| 2. | 28/07/2023 | Poster making competition | Students of all dept. | Students got the opportunities to showcase their technical skill through various posters. |

| 3. | 05/09/2023 | Teachers Day Celebration | SE,TE | Fostered a sense of appreciation & respect for educators, strengthened student-teachers bond. |

| 4. | 15/10/2023 | First year students conclave | FE | Introducing first year students to the faculty and course introduction, syllabus, assessment, examination patterns, specialization introduction, career opportunities, training-placement orientation, ice breaking session & college campus visit. |

| 5. | 12/03/2024 To 14/03/2024 | Group Discussion, Debate Competition, Extempore | SE,TE | These activities provided A&R students with engaging experiential learning opportunity that promotes teamwork, creativity, problem-solving, leadership development, time management and reflection, contributing to their holistic education and professional development. |

| 6. | 14/04/2024 | Dr. Babasaheb Ambedkar & Mahatma Jyotiba Phule Jayanti Celebration | Students and Staff Members of all dept. | Students & Faculty members celebrate birth anniversary to honor and remember their remarkable contribution for India. |

| 7. | 18/04/2024 To 20/04/2024 | Excalibur 2K24 | SE,TE | Students got the opportunities to organize, co-ordinate and manage technical event as well as showcase their technical skill through various events like software programming, robo war, robo race, paper/poster presentation, lathe war etc. |

| Academic Year: 2022-23 | ||||

| 1. | 12/10/2022 To 14/10/2022 | Group Discussion, Debate Competition, Extempore | SE | Boost confidence |

| 2. | 15/09/2022 | Engineers day celebration | SE | -- |

| 3. | 05/09/2022 | Teachers day celebration | SE | -- |

|

|

|

|

|

|

|

|

| Sr. No | Date | Name & Address of company | Class | Outcome |

|---|---|---|---|---|

| Academic Year: 2024-25 | ||||

| 1. | 25/02/2025 | Faith Automation, Pune | SE | Students gained firsthand exposure to the operations, processes, and challenges faced by automation and robotics industries, enhancing their understanding of industrial ecosystems and business operations. |

| 2. | 28/02/2025 | Shriram Industries, Nashik | TE | Students gained firsthand experience of the manufacturing processes, quality control measures and supply chain management practices employed in the manufacturing industries. |

| 3. | 20/08/2024 | Avdhoot Technocrats Pvt. Ltd. Nashik. | SE | Students gained firsthand experience of the manufacturing processes, quality control measures and supply chain management practices employed in the automotive and engineering industries, enriching their understanding of theoretical concepts taught in the classroom. |

| 4. | 23/08/2024 | Metalman Auto Private Limited, Ch. Sambhajinagar | TE | Students gained firsthand experience of the manufacturing processes, quality control measures and supply chain management practices employed in the manufacturing industries. |

| 5. | 04/10/2024 | Armstrong Dematic, Nashik. | BE | Students gained firsthand exposure to the operations, processes, and challenges faced by automation and robotics industries, enhancing their understanding of industrial ecosystems and business operations. |

| Academic Year: 2023-24 | ||||

| 1. | 02/05/2024 | American Axle & Manufacturing Ltd. Pune. | SE | Students gained firsthand experience of the manufacturing processes, quality control measures and supply chain management practices employed in the automotive and engineering industries, enriching their understanding of theoretical concepts taught in the classroom. |

| 2. | 01/02/2024 | Rajhans dudh sangh, Sangamner | SE | Students gained firsthand experience of the manufacturing processes, quality control measures and supply chain management practices employed in the food processing industries. |

| S.B.T. Sahakari Sakhar Karkhana, Sangamner | ||||

| 3. | 14/02/2024 | Unique Circle Engineering Pvt. Ltd. Pune. | TE | Students gained firsthand exposure to the operations, processes, and challenges faced by automation and robotics industries, enhancing their understanding of industrial ecosystems and business operations. |

| Faith Automation Pvt. Ltd Pune. | ||||

| Academic Year: 2022-23 | ||||

| 1. | 20/03/2023 | Techno shell Pvt. Ltd, Nashik. | SE | Students learnt various automation processes |

| 2. | 23/09/2022 | HAL Aerospace Museum, Nashik. | SE | Students get information about various fighter aircrafts. |

|

|

|

|

|

|

|

|

| Sr. No. | Date | Name of Resource Person (Post, Name of Company) | Area/Subject | Target audience | Outcome |

|---|---|---|---|---|---|

| Academic Year: 2024-25 | |||||

| 1. | 19/04/2025 | Mr. Sagar Thorat, Infinity Automation | Designing & Career Opportunities | SE, TE, BE | Students gained valuable insights into the career in design domain. |

| 2. | 22/04/2025 | Mr. Dnyaneshwar Wahadhne, TATA Consultancy Services | Career Opportunities for Engineers | SE, TE, BE | Students gained valuable insights into the career opportunities after BE. |

| 3. | 23/04/2025 | Dr. Bharat Suryawanshi, Assistant Controller of Patents & Designs, Nagpur | Protecting Intellectual Property Rights & IP Management for Startups | SE, TE, BE | Students gained valuable insights into the IPR. |

| 4. | 21/10/2024 | Prof. Yogita Bhagwat, Dept. of ETC, AVCOE, Sangamner | Basics of Electronics | SE | Students gained valuable insights into the basic electronic components. |

| Academic Year: 2023-24 | |||||

| 1. | 05/09/2024 | Dr. Sadanand Bhosale, Director, NSS, SPPU, Pune | Hindi Literature | Faculty Members of all dept | Faculty members gained valuable insights into the Hindi Literature. |

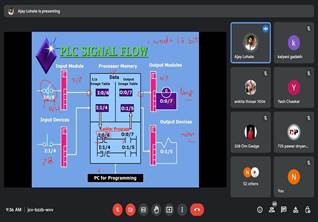

| 2. | 06/10/2023 |

Mr. Sreedhar Makam, Senior Manager Final Assembly, HAL, Nashik |

Role of Automation - PLC in industries | SE, TE | Students gained insights into the practical applications of PLC & how they are applied in real world automation scenarios, enhanced their understanding of the subject matters. |

| 3. | 24/02/2024 | Mr. Mangesh Khilari, IPS Officer | Competitive Exam preparation | SE, TE | Students got the opportunity to connect with IPS officer and gained knowledge about diverse career paths available through UPSC, helping them explore potential career options and make informed decisions about their future career paths. |

| 4. | 05/04/2024 |

Mr. Parag Shah, Founder, Unique Circle Engg. And Automation, Pune |

Industry 4.0: Being an Entrepreneur | SE, TE | The program helped students develop an entrepreneurial mindset by fostering creativity, innovation, and risk-taking behavior, empowering them to identify and pursue opportunities for business creation and growth. |

| 5. | 07/04/2024 | Mr. Abhijeet Bhand, Director, Kanadlab | IPR Awareness | TE | Students gained up-to-date knowledge about the legal framework governing the IPR and its importance, including patent and copyright. |

| 6. | 08/04/2024 | Mr. Pratik Kuldharan, Just Engineering, Pune | Recent trends, scope, opportunities and challenges in Automation and Robotics | SE, TE | Students gained valuable insights into the current trends, challenges & opportunities within the Automation and Robotics. |

| Academic Year: 2022-23 | |||||

| 1. | 09/03/2023 | Mr. Avari | Orientation program on communication skill | SE | Students learnt importance of communication skill in job opportunity |

| 2. | 11/10/2022 |

Mr. Lalit Bangera,

Siemens, Singpore |

Automation in process industries | SE | Students got idea about process automation |

|

|

|

|

|

|

|

| Sr. No. | Date | Name of Activity | Resource person | Target audience | Outcome |

|---|---|---|---|---|---|

| Academic Year: 2024-25 | |||||

| 1. | 09/10/2024 To 11/10/2024 | Three days’ workshop on “RPA-Ui Path Tool” | Mr. Ismail Nagnoor, Ascent Software | BE | Students gained valuable insights into the robotic process automation |

| 2. | 30/09/2024 To 03/10/2024 | Four days’ workshop on “Siemens PLC programming with HMI designing” | Mr. Pradeep Nehe, Falcon Automation Technologies. | TE | Students gained valuable insights into the PLC, HMI & SCADA. |

| 3. | 23/07/2024 To 25/07/2024 | Three days’ workshop on “Application of Ansys in research” | Mr. Suresh Kumar, Mr. Rohit Sangawan, ARK info solutions | Faculty Members | Faculty members gained valuable insights into the Matalb. |

| Academic Year: 2023-24 | |||||

| 1. | 21/08/2023 To 23/08/2023 | Industrial robotics simulation software workshop: RoboDK |

Mr. Pranav Lad, iTech Robotics and Automation Pvt. Ltd. |

SE | Students learnt to do simulation by using RoboDK software. |

| 2. | 26/10/2023 To 29/10/2023 | Four days’ workshop on “Programmable Logic Controller (PLC)” |

Mr. Vivek Sardal, Regional Manager, Prolific Automation Pvt. Ltd. |

TE | Students gained valuable insights into the PLC, HMI & SCADA. |

| 3. | 07/11/2023 | Webinar on “MATLAB” |

Mr. Subhajit Goswami, Sales Executive, Matlab |

Faculty Members | Faculty members gained valuable insights into the Matalb. |

| 4. | 03/04/2024 To 04/04/2024 | Two days’ Workshop on "Robot Operating System (ROS)" | Mr. Raunak Chaudhari, Mr. Pratik Gawali, AUTOMAX Robotics Pvt. Ltd., Pune | TE | Students acquired practical skills and knowledge related to ROS. |

| Academic Year: 2022-23 | |||||

| 1. | 16/03/2023 To 18/03/2023 | Three days’ National Workshop on “Recent Advances in Robotics” | Various experts from renown institutes like IIT, NIT and industries like i-Robotics etc. | SE | Students learnt what advancement is going on in robotics. |

| 2. | 15/02/2023 | One day workshop on “Introduction to Robotics” |

Mr. Gaurav Singh

Director Thinker Station |

FE | Students learnt basics of robotics |

| 3. | 14/11/2022 To 15/11/2022 | Two days’ workshop on “Geometric Dimensioning &Tolerancing” |

Mr. Gajanan Trikutkar

Founder DEQual Technologies |

SE | Students learnt Drawing reading, Dimensioning, Tolerances & Allowances |

| 4. | 05/09/2022 To 08/09/2022 | Four days’ Workshop on "Industrial Automation" |

Mr. Ajay Lohate

(Infinity Automation Institute, Pune) |

SE | Students learnt various concepts of Industrial Automation |

|

|

|

|

|

|

|

|

|

|

|

| Sr. No. | Date | Title | Venue | Name of The Participant | Outcome |

|---|---|---|---|---|---|

| Academic Year: 2022-23 | |||||

| 1. | 26/04/2023 To 27/04/2023 | PLC trainer training | AVCOE, Sangamner | All Faculty Members | Concepts have been cleared |

| 2. | 01/03/2023 To 05/03/2023 | National level FDP on “Innovation, Research and IPR - Journey towards excellence” | Online (SPCE Mumbai, SAE India & IIC) | Prof. N. Varpe | Get information about IPR in research |

| 3. | 09/02/2023 | NPTEL E-Awareness workshop on | Online (NPTEL) | All Faculty Members | Awareness about NPTEL courses |

| 4. | 02/02/2023 | IP Awareness training program under NIPAM | Online (Intellectual Property Office, India) | Prof. N. Varpe | Get information about IPR |

| 5. | 13/12/2022 To 14/12/2022 | MasterCAM 2023 training | AVCOE, Sangamner | BRB, HPP, PBW, VSG, MJT, NJV, SKB | Concepts have been cleared |

| 6. | 01/08/2022 To 05/08/2022 | Workshop on “Designing and Modelling of IOT, AI & ML Systems” | Online (AICTE ATAL) | Prof. N. Varpe | Concepts have been cleared |

| Academic Year: 2021-22 | |||||

| 1. | 07/03/2022To 11/03/2022 | STTP through ICT mode on “Advanced Welding Processes” | Online (National Institute of Technical Teachers Training and Research, Kolkata) | Prof. N. Varpe | Concepts have been cleared |

| 2. | 04/03/2022 | Online non-credit course on “RPA Lifecycle:Introduction, Discovery and Design” | Online (Automation Anywhere offered through Coursera) MOOC | Prof. N. Varpe | Concepts have been cleared |

| 3. | 24/02/2022 | National webinar on “New Product Development” | Online (Bharatiya Vidya Bhavan's Sardar Patel College of Engineering in collaboration with SAE India Western Section) | Prof. N. Varpe | Concepts have been cleared |

| 4. | 14/02/2022To 18/02/2022 | Short term course on “Curriculum Design and Development” | Online (Dr. M.G.R. Educational and Research Institute, Chennai and Meston College of Education, Chennai, Tamil Nadu) | Prof. N. Varpe | Concepts have been cleared |

| 5. | 23/08/2021 To 27/08/2021 | FDP on “Robotics:Advances and Applications” | Online (AICTE ATAL) | Prof. N. Varpe | Concepts have been cleared |

| 6. | 14/08/2021 | Webinar on “Patent First Publish Later” | Online (Bundelkhand Institute of Engineering and Technology, Jhansi, SPIU-UP and Indian Institute of Patent and Trademark Attorny) | Prof. N. Varpe | Concepts have been cleared |

|

|

|

|

| Sr. No | Academic Year | Total No. of students | Total No. of Students Placed Through Campus | Total No. of Students for Higher Studies | Lowest Package (LPA) | Highest Package (LPA) |

|---|---|---|---|---|---|---|

| 1 | 2024-2025 | 50 | 43* | 02 | 3.00 | 6.00 |

| Sr No | Name of Student | Photo of the student | Mobile No. | Email ID | Name of Company with Location | Selection for the post | Pay Scale / CTC in LPA |

|---|---|---|---|---|---|---|---|

| Academic Year: 2024-25 | |||||||

| 1 | Kawade Ganesh P. |

|

7756867690 | kawadeganesh81@gmail.com | Fanuc | GET | 6.0 |

| 2 | TAMBE SUDHIR SANJAY |

|

9359233410 | sudhirtambe2003@gmail.com | Johnson Controls | GET | 5.6 |

| 3 | WAKCHAURE ADITYA .S |

|

9075327995 | adityawakchaure14@gmail.com | Skill Intern Pvt.Ltd | GET | 5.2 |

| 4 | KAWADE PRASAD SHAM |

|

9604919092 | prasadkawade0@gmail.com | Skill Intern | GET | 5.2 |

| 5 | DHOKARE SUMIT SURESH |

|

7020799454 | sumitdhokare480@gmail.com | Skill Intern | GET | 5.2 |

| 6 | THOKALE SHREYAS SUDHAKAR |

|

7276982107 | shreyasthokale@gmail.com | Skill Interns Pvt.Ltd.. | Trainee | 5.2 |

| 7 | DIGHE ANIKET LAXMAN |

|

9921460192 | digheaniket64@gmail.com | skill Interns | GET | 5.2 |

| 8 | CHHHUTKE PRATHMESH DATTATRA |

|

8605044190 | prathmeshchutke007@gmail.com | Skill Interns Pvt.Ltd.. | Trainee | 5.2 |

| 9 | Kawade Ganesh P. |

|

7756867690 | kawadeganesh81@gmail.com | Bosch | GET | 4.5 |

| 10 | BHAGWAT AKSHADA BALASAHEB |

|

9373336366 | akshadabhagwat2019@gmail.com | Mahindra & Mahindra | GAT | 4.2 |

| 11 | KACHALE SNEHAL ANKUSH |

|

9422261095 | snehalkachale2003@gmail.com | Mahindra & Mahindra | GAT | 4.2 |

| 12 | SONWANE POOJA SITARAM |

|

8010464545 | 123pooja04@gmail.com | Mahindra & Mahindra | GAT | 4.2 |

| 13 | HAJARE NIIKHIL LAXMAN |

|

9322637245 | hajaren29@gmail.com | Armstrong Dematic | GET | 4.0 |

| 14 | DIGHE ANIKET LAXMAN |

|

9921460192 | digheaniket64@gmail.com | Automated Industrial Projects | GET | 3.6 |

| 15 | DESHMUKH KARTIK |

|

8767062134 | deshmukhkartik1111@gmail.com | Automated Industrial Projects | GET | 3.6 |

| 16 | GORDE ADITI SATISH |

|

9405400491 | aditisatishgorde@gmail.com | Automated Industrial Projects | GET | 3.6 |

| 17 | DIGHE ANIKET LAXMAN |

|

9921460192 | digheaniket64@gmail.com | RAZK Industrial Automation Private Limited | GET | 3.6 |

| 18 | HASE ONKAR BALU |

|

8600298165 | onkarhase4142@gmail.com | RAZK Industrial Automation Private Limited | GET | 3.6 |

| 19 | KALE ABHISHEK SUBHASH |

|

9511701972 | abhishekkale0804@gmail.com | RAZK Industrial Automation Private Limited | GET | 3.6 |

| 20 | THAKARE SANKET UJVAL |

|

9307527664 | sanketthakare11042002@email.com | RAZK Industrial Automation Private Limited | GET | 3.6 |

| 21 | PAWASE ADESH RAMESH |

|

8600425716 | adeshpawase4@gmail.com | RAZK Industrial Automation Private Limited | GET | 3.6 |

| 22 | SHELKE ONKAR RAJENDRA |

|

9021314192 | onkarshelke33@gmail.com | KSB | GET | 3.00 |

| 23 | SURYAWANSHI SANKET AMBADAS |

|

9145744137 | sanketsuryawanshi914574@gmail.com | Aashida Electronic Pvt.Ltd. | GET | 3.5 |

| 24 | THITAME KARTIK SANTOSH |

|

8805758661 | kartikthitame6@gmail.com | Aashida Electronic Pvt.Ltd. | GET | 3.5 |

| 25 | DESHMUKH KARTIK |

|

8767062134 | deshmukhkartik1111@gmail.com | Kligenberg Pvt.Ltd. | GET | 3.07 |

| 26 | DIGHE ANIKET LAXMAN |

|

9921460192 | digheaniket64@gmail.com | Kligenberg Pvt.Ltd. | GET | 3.07 |

| 27 | CHHHUTKE PRATHMESH DATTATRA |

|

8605044190 | prathmeshchutke007@gmail.com | L-Cube | Trainee | 3.0 |

| 28 | GADAKH KALYANI SANJAY |

|

9307137377 | kalyanigadakh2004@gmail.com | Schaeffler India Pvt.Ltd. | GET | 3.07 |

| 29 | PAWAR SAKSHI SANDIP |

|

7776947219 | pawarsakshi9677@gmail.com | Schaeffler India Pvt.Ltd. | GET | 3.00 |

| 30 | TAJANE ISHWARI NITIN |

|

9325100828 | ishwaritajane@gmail.com | Schaeffler India Pvt.Ltd. | GET | 3.00 |

| 31 | POKHARKAR PARIMAL SANJAY |

|

9370369376 | Parimalpokharkar@gmail.com | Kukson Electronic Pvt.Ltd. | GET | 3.0 |

| 32 | THOKALE SHREYAS SUDHAKAR |

|

7276982107 | shreyasthokale@gmail.com | Kukson Electronic Pvt.Ltd. | GET | 3.0 |

| 33 | THAKARE SANKET UJVAL |

|

9307527664 | sanketthakare11042002@email.com | Gandhi Automation | GET | 3.0 |

| 34 | SANGALE SHIRISH BABAN |

|

9359745542 | shirishsangale11@gmail.com | Gandhi Automation | GET | 3.0 |

| 35 | DESHMUKH KARTIK |

|

8767062134 | deshmukhkartik1111@gmail.com | Grandious Automation | GET | 3.00 |

| 36 | THOKALE SHREYAS SUDHAKAR |

|

7276982107 | shreyasthokale@gmail.com | Grandious Automation | GET | 3.00 |

| 37 | SANGALE SHIRISH BABAN |

|

9359745542 | shirishsangale11@gmail.com | Grandious Automation | GET | 3.00 |

| 38 | GORDE ADITI SATISH |

|

9405400491 | aditisatishgorde@gmail.com | Grandious Automation | GET | 3.00 |

| 39 | TAKATE PRAGATI JAGDISH |

|

9699717113 | pragati7219@gmail.com | Grandious Automation | GET | 3.00 |

| 40 | RAHANE TANUJA GORAKSHA |

|

9356868961 | rahanetanuja621@gmail.com | Grandious Automation | GET | 3.00 |

| 41 | GAVANDE RUTUJA DASHRATH |

|

80106880224 | rutujagavande10@gmail.com | Lean Automation | GET | 3.00 |

| 42 | TAMBE KAVERI SUKHDEV |

|

9075512060 | kaveritambe2611@gmail.com | Lean Automation | GET | 3.00 |

| 43 | WABLE SHRADDHA .A |

|

7058408036 | shraddhawable132004@gmail.com | Lean Automation | GET | 3.00 |

1. Department has started Incubation centre at central workshop.

2. Department has started Robotics training centre (e-yantra) in

association with IIT Bombay.

3. AeSI Students chapter in association with Aeronautical Society of India

(HAL) has been started.